Induction Motor Elements

Induction Rotors & Stators for High Performance Applications

Induction motors are the “work-horses” of the rotating machinery field. Simple, rugged construction and the ability to handle high temperatures allow them to withstand difficult environments.

2-pole machines tend to be smaller, simpler motors running at high speed; but larger, higher power motors can also be constructed in this configuration. The attraction of the 2-pole design is the ability to use a lower frequency (less expensive) drive.

4-pole machines are high-performance, high-power devices with large rotor bores and offer a greater energy density than 2-pole machines; 6/8 pole motors are for high-torque, lower speed applications.

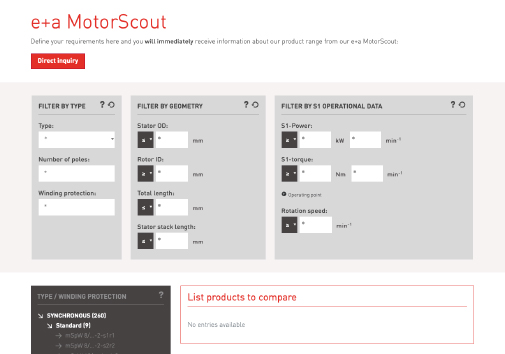

e+a MotorScout

-

MotorScout

MotorScout is e+a’s online database of commercial motor types for both Induction and PM synchronous Motor/Generators.

Input required motor characteristics and MotorScout will return a list of design possibilities that could work in your application, both Induction and PM. If MotorScout does not return any possibilities, e+a may still have designs for those requirements. Contact us directly.

Visit: https://motorscout.eunda.ch

Contact: mdrumm@eandausa.com and let an e+a engineer recommend a solution to fit your needs.

Technical information at your fingertips enabling informed decisions.

Contact us today with any questions!

Induction Motor Elements

-

Aluminum Rotors

Rotors with a squirrel cage made of die-cast aluminum have a maximum circumferential speed (tip speed) of approximately 130 m/s. They are inexpensive solutions for cost sensitive projects, have a long service life and a small rotor weight. An aluminum alloy is an option to pure aluminum rotors for achieving higher tip speeds (180 – 200 m/s depending on geometry) but at a reduced performance.

-

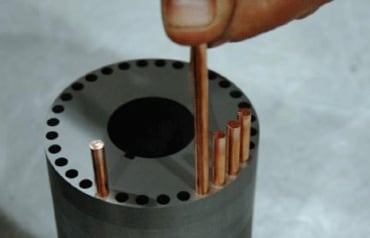

Copper Rotors

Copper rotors (with nominal tip speeds of 100 m/sec) distinguish themselves with a considerably larger rotor bore and less additional losses than aluminum rotors. In e+a's special configuration with a short circuit ring for reinforcement they can spin up to 220 m/sec.

-

ASMpro with Copper Profile

The e+a series of induction motor elements with copper profile rotors combines the advantages of PM synchronous machines with those of asynchronous devices. Unlike PM machines, these rotors use no magnets. They have a temperature resistant rotor, require no voltage protection module, are simple to start up, simple to control and have a broad speed range even without using a speed sensor. Motor elements from the ASMpro series are particularly suitable for applications requiring high torque and a wide speed range.

-

Special Design with Copper Rotors

e+a offers its own series of high pole-count asynchronous machines with special copper rotors for applications requiring high torque and a wide speed range (popular application is machining of titanium). They are characterized by high torques at low speeds for a simultaneously large field weakening range. In comparison to permanent magnet machines, these motors can accept a higher thermal load and are second to none in providing prodigious torque. In contrast to most applications involving PM motors, a voltage protection module is not required.